bar3

Our latest 1100V Isolation barrier is compliant with all relevant statutory and industry standards including AS2081:2011.The bar3 is a three phase unit designed to isolate high voltages from detection equipment.

Drawing on more than four decades of proven engineering experience, m-tronix designs and manufactures a complete range of electrical protection, monitoring and control systems for mining and heavy industry.

Every product has been re-engineered and modernised, delivering higher reliability, faster build times and improved manufacturing efficiency while lowering production costs and maintaining full compliance with AS/NZS and IEC standards.

Highly proven in operation, m-tronix relays and control modules are compact, cost-effective and designed for the world’s most challenging environments — including those requiring intrinsic safety and advanced fault-tolerant performance.

Available in both microprocessor and hardware-based configurations, the range incorporates numerous standard protection and monitoring features that have evolved from the original Bramco designs through continuous refinement and testing.

Historically, m-tronix technology has achieved Mines Department approvals in Australia and South Africa, demonstrating its long-standing reputation for reliability, safety and engineering excellence.

Our latest 1100V Isolation barrier is compliant with all relevant statutory and industry standards including AS2081:2011.The bar3 is a three phase unit designed to isolate high voltages from detection equipment.

Our new bar4 1100V Isolation barrier is a three-phase unit designed to isolate high voltages from detection equipment. The bar4 is a physically smaller unit than the bar3 and is DIN rail mounted. Designed for use with the all-new GFL3 Earth Leakage, Frozen Contactor, Ground Fault Lockout micro-controlled relay.

Our new EFX Relay recently completed six months of field trials and compliance tests. Designed to meet AS2081:2011, it provides latest micro-processor technology to provide unrivaled control for Earth Leakage, Ground Fault, Lockout and Frozen contactor in one small din-rail mounted product.

iF is designed to detect a leakage of voltage across a switching device of 24volts or more when the switching device is supposedly in the open or tripped position. A barrier is used in conjunction with this relay.

el3 provides advanced Earth Leakage protection and is compliant to the latest Australian standards, including AS2081:2011. Utilising microprocessor technology el3 provides next generation EL protection to VVVF drives.

elf3 detects earth fault currents flowing in a power system and provides visual indication of earth leakage conditions. The elf3 is specifically designed to protect systems supplying VF drives and provides very high immunity to converter noise.

elec2-f is a fascia mounted, combination of our el3 Earth Leakage protection technology, with our iC3 Earth continuity and pilot control. It is compliant with the latest Australian standards, including AS2081:2011. Utilising microprocessor technology, provides next generation EL protection to VVVF drives

elec2-d is a din-rail mounted, combination of our el3 Earth Leakage protection technology, with our iC3 Earth continuity and pilot control. It is compliant with the latest Australian standards, including AS2081:2011. Utilising microprocessor technology, provides next generation EL protection to VVVF drives

iAB is compliant to latest statutory and industry standards. iAB, has been designed to detect Earth Fault Currents flowing in a power system.

iC1 has been designed to provide Earth Continuity and Pilot Control monitoring of a supply cable by grounding the load end of the pilot core via a diode to earth. Local/Remote start operation is selectable. Leaders in Innovative Protection Systems, the iC1 is compliant to the latest Australian standards, including

AS2081:2011.

iC3 Earth Continuity and Pilot Control Relay is designed to actively monitor the Resistance of the Pilot Earth circuit in a supply cable by diode termination. The iC3 utilises microprocessor technology to provide a greater level of stability over longer pilot cables by using digital filtering

techniques. The microprocessor also performs continual self-diagnostics to prevent false tripping or failure to operate. iC3 is compliant to latest Australian standards, including AS2081:2011.

iC Earth Continuity Relay has been designed to monitor the continuity of the Earth Circuit in a supply cable by grounding the pilot core via a diode, polarised positive to earth.

elec2-f is a fascia mounted, combination of our el3 Earth Leakage protection technology, with our iC3 Earth continuity and pilot control. It is compliant with the latest Australian standards, including AS2081:2011. Utilising microprocessor technology, provides next generation EL protection to VVVF drives

elec2-d is a din-rail mounted, combination of our el3 Earth Leakage protection technology, with our iC3 Earth continuity and pilot control. It is compliant with the latest Australian standards, including AS2081:2011. Utilising microprocessor technology, provides next generation EL protection to VVVF drives

iD has been designed to monitor the continuity of the Earth Circuit in a supply cable by grounding the pilot core via a diode, polarised positive to earth, and to allow remote start/stop operation by momentarily shorting a 100 Ohm resistor in the pilot circuit (which closes the relay) and opening the pilot with a stop button to open

the relay.

nlm3 Neutral Link Monitor relay is a legacy (introduced in 2005) integrity protection product designed to continuously monitor the current limitation system on the secondary star point to earth connection of a supply transformer.

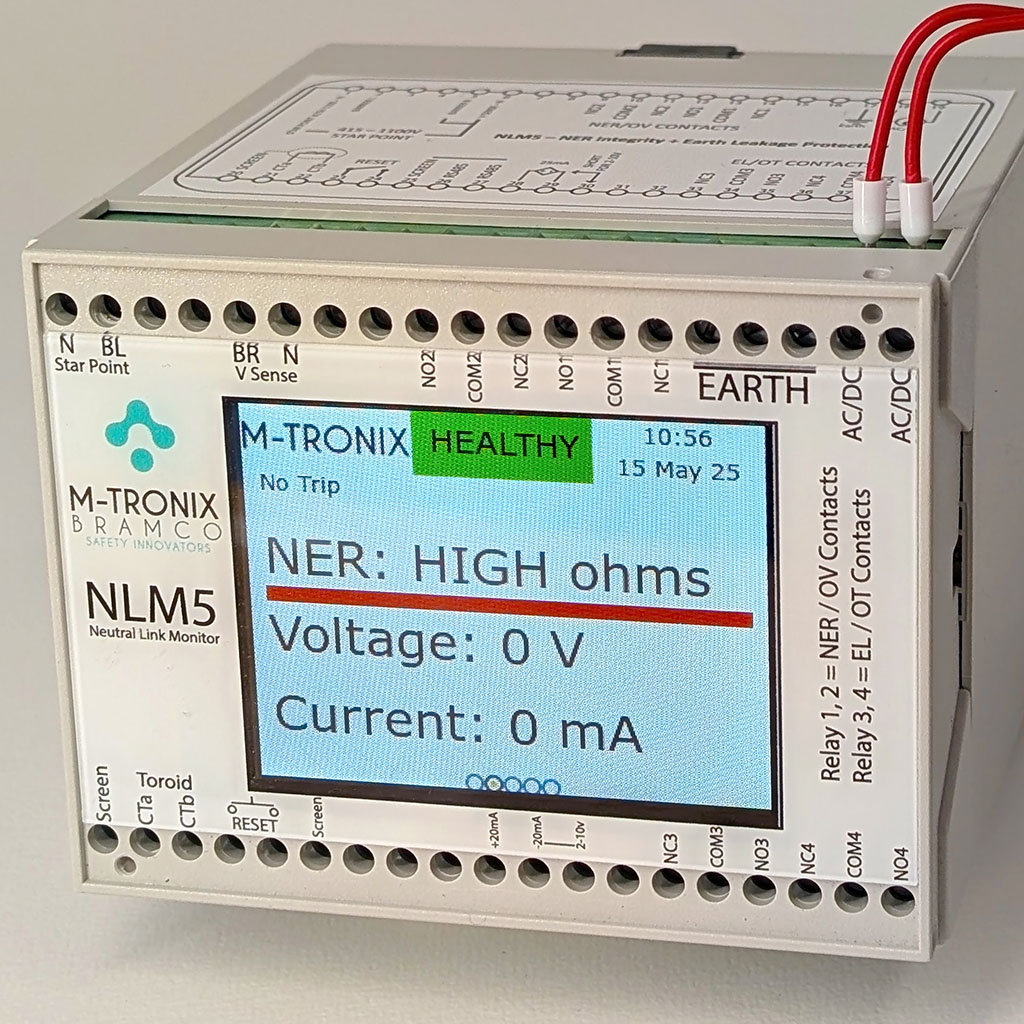

nlm5 Neutral Link Monitor represents the latest generation of neutral-to-earth monitoring. Providing advanced continuous supervision of the Neutral Earthing Resistor (NER) circuit, monitoring resistance integrity, neutral-earth voltage rise, and leakage current. Trip thresholds and delays are independently adjustable, allowing accurate coordination with upstream protection devices. Designed for Australian mining and heavy-industrial applications, the NLM5 is compact, cost-effective and fully compliant with AS/NZS 2081:2011 and IEC 61010.

pcm provides automatic submersible-pump control using adaptive snooze/no-load detection. Designed on proven Bramco engineering, the PCR uses real-time motor current monitoring to determine when a pump is running under load, snoring, or drawing no load — and then automatically stops or starts the pump accordingly. It is designed and manufactured in accordance with ISO9001:2000 certified company standards. It is compliant with AS2081:2011.

PCX takes our PCM and adds adaptive control algorithm which continually adjusts run and pause times, delivering highly efficient pumping with reduced dry-run damage and lower maintenance costs. The PCX is designed for mining, tunnelling, construction, dewatering and industrial pump applications where automated.

PCX has a remote operating module, providing compete stop/start flexibility and safe set-up and operation with graphic display tracking performance data. It is compliant with AS2081:2011, and designed and manufactured to ISO9001:2000.

Introduced in 1984, and continuously developed for almost forty years, this highly advanced package offers Control and Protection for powered outlets, controlling machines or electrical installations. Leaders in Innovative Protection Systems, the cpm is compliant to latest statutory and industry standards cpm-plus is the most advanced product in the cpm range.

The mpm is compliant to latest statutory and industry standards. The advanced Motor Protection Module mpm has been designed to cover critical protection features in one industrial module. The mpm can function independently or in networked operations.

pcm provides automatic submersible-pump control using adaptive snooze/no-load detection. Designed on proven Bramco engineering, the PCR uses real-time motor current monitoring to determine when a pump is running under load, snoring, or drawing no load — and then automatically stops or starts the pump accordingly. It is designed and manufactured in accordance with ISO9001:2000 certified company standards. It is compliant with AS2081:2011.

PCX takes our PCM and adds adaptive control algorithm which continually adjusts run and pause times, delivering highly efficient pumping with reduced dry-run damage and lower maintenance costs. The PCX is designed for mining, tunnelling, construction, dewatering and industrial pump applications where automated.

It offers a remote operating module, providing compete flexibilty and safe set-up and operation with graphic display tracking performance data. It is compliant with AS2081:2011, and designed and manufactured to ISO9001:2000.

The PRM2 Phase Rotation/Loss Monitor from m-Tronix is a next-generation protection device for three-phase electrical systems, offering reliable monitoring of phase rotation, phase loss, undervoltage, and advanced safety functions such as Earth Leakage Lockout and Frozen Contactor Protection.

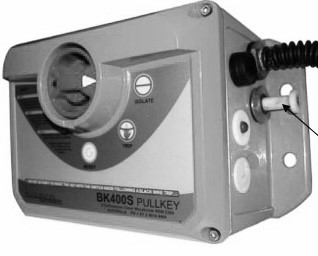

The BK400 Pullkey is a lanyard switch designed to provide pull wire protection on conveyors, it is available in two models. These is the BK400S – single shafted key, which operates in a balanced pullwire configuration and the BK400D dual shafted key, where the two pullwires operate mechanically independent of one another. Flexible Design to Suit all Applications.

We have to-date supplied over 300 systems worldwide and to countries such as Australia, Sth Africa, Zambia, USA, Brazil, Peru, Ukraine, Belarus and others. Our Conveyor Control System is both powerful and flexible with the latest in self diagnostics. All faults along the system are displayed on the control screen. Our Conveyor Control system embodies the requirements of Occupational Health and Safety Acts, duty of care and is operationally Totally Fail Safe.

Temperature compensation is necessary where variations in temperature will cause the length of the pull wire to vary.

This we achieve by supplying a Tension Assembly to accept the extensions of the wire and the distribution back into the

system when movement occurs.

The LLi is a compact, panel mounted, low power, three phase monitor device to provide visual indication of load phases being present. The three load phases and Earth are connected to the LLi.

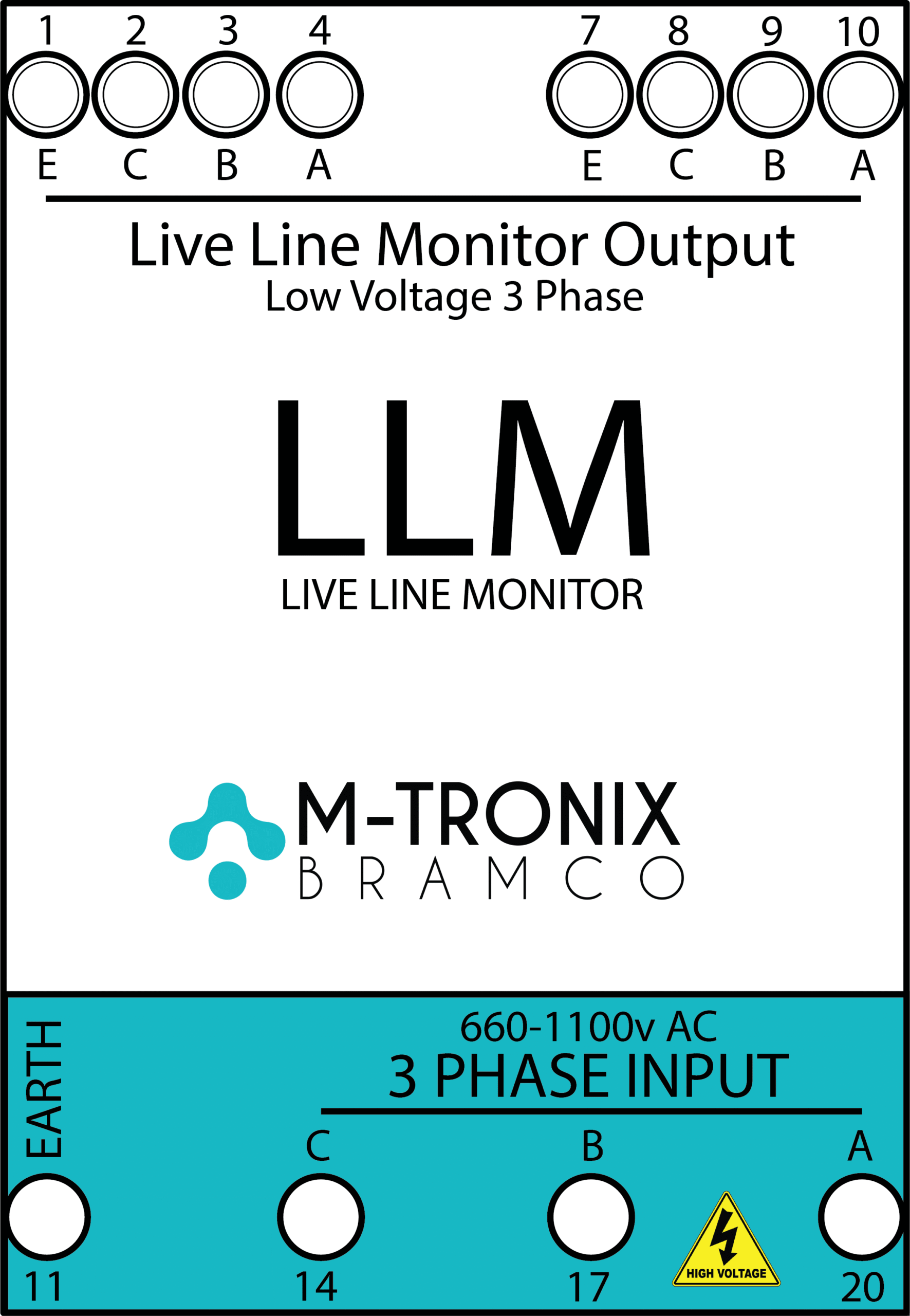

The LLm Module is a compact, DIN or screw mounted, low power, three phase input device to provide visual indication of load phases being present. The three load phases and Earth are connected to the LLM module.

LLi2 is a compact, panel mounted, low power, three phase monitor device to provide visual

indication of load phases being present. The three load phases and Earth are connected to the LLi2.

LLi3 is a compact, easily understood 3-phase AC circuit status indicator built upon decades of proven Bramco technology, engineered and continuously developed by M-tronix for live-line indication.